Premium architectural and industrial finishes

Powder Coatings

Dulux Powder Coatings deliver superior colour solutions by taking the uncertainty out of your project with premium warranty grade powder coatings and application via a network of Accredited Powder Coaters who meet strict international standards. Pictured: James Cook University, 2019 Dulux Colour Awards finalist. Photograph: Andrew Rankin.

Dulux Colour Awards 2024 finalists revealed

More than 80 design firms have been named as finalists from a record number of entries in the Dulux Colour Awards.

New trends launched

Download our Dulux Colour Forecast 2024 brochure featuring 36 Dulux colours and 12 Dulux Powder Coating shades.

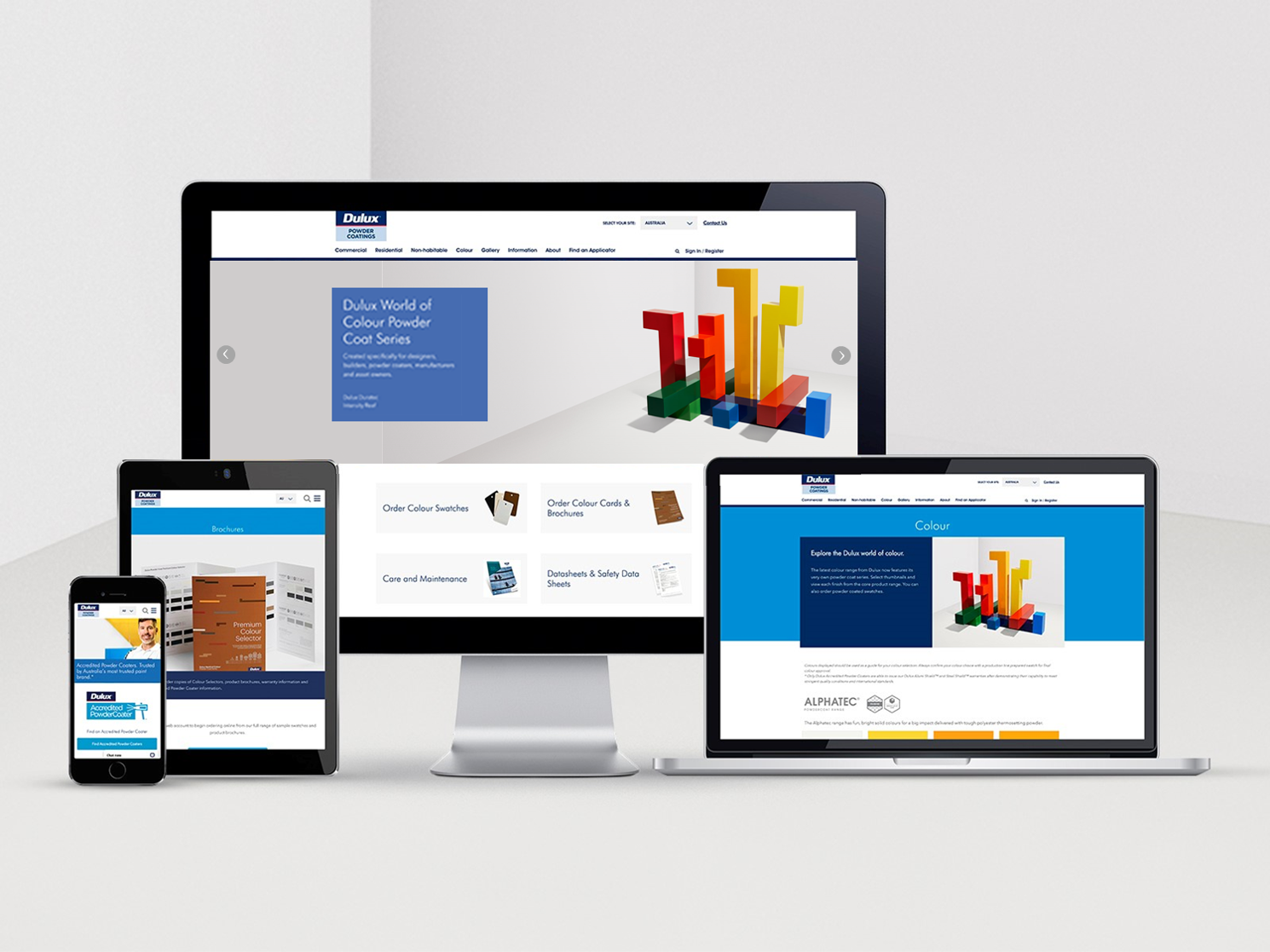

Powder coatings website

Discover in-depth information including product, colour, specification and recommended applicators on our website. You can also order sample swatches, colour cards and product brochures.

Explore the colour range

Explore the range of powder coating colours and finishes.

Order swatches

Order powder-coated swatches from our dedicated website. A separate registration/log in is required to access this sample service.

Services

Advice and specifications

It has never been easier to have your powder coating enquiries answered. Our dedicated specification consultants are available to give you product selection advice, specification requests and sample colour swatch ordering.

Find a Dulux Accredited Powder Coater

By selecting a Dulux Accredited Powder Coater, you can guarentee that you're getting the best for your project. Dulux Powder Coatings are an ideal choice for the long-term protection of architectural aluminium and steel items for your next project, and provide assurance through the issue of Alumi Shield™ and Steel Shield™ warranties.