Products for Professional Applicators

Trade Products

A comprehensive range of premium products and specialty finishes at your fingertips.

Our brands

envirO₂™

- Interior

- Premium

At Dulux, we’re committed to providing more eco-conscious and sustainable products. Our newest formula, Dulux envirO₂™, offers premium quality and environmentally responsible options when it comes to all of your painting needs.

Wash&Wear®

- Interior Paint

- Wall Paint

Our Dulux Wash&Wear formula ensures your walls stay looking freshly painted for longer.

Weathershield®

- Exterior

- Walls

Dulux Weathershield has been specially designed to provide a tough, hardwearing finish that provides protection from all weather conditions.

Renovation Range

- Interiors

- Kitchen

- Bathroom

Our revolutionary, water-based range of coatings are perfect for painting surfaces in the kitchen, bathroom or laundry.

Super Enamel™

- Doors, Windows, Trims

- Interior Paint

- Exterior Paint

Our water-based and oil-based enamel paints are designed to provide a hard-wearing finish for your doors, architraves, skirting boards and window frames - ideal for bathrooms, kitchens and laundries.

Precision®

- Preparation Paint

- Interior Paint

Dulux PRECISION product range has been developed with new, improved formulations delivering superior performance. It offers a precise solution to your surface problems, where a multi-purpose preparation product wont suffice.

Professional®

- Interior

- Exterior

Dulux Professional® provides a range of paint solutions for your residential and commercial project needs.

Acratex® Membrane & Elastomeric Topcoat

- Exterior

Acratex® elastomeric topcoats provide ultimate protection for masonry substrates delivering barrier coat protection against the damaging ingress of moisture, carbon dioxide and chloride ion contaminants.

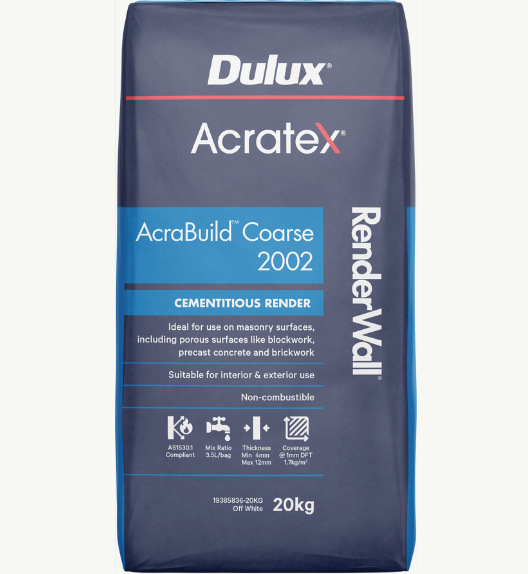

Acratex® Render

Acratex® RenderWall is a preparatory base leveling product designed for system use with subsequent Acratex® Acrylic Texture Systems. It is a cementitious render to level irregularities and produces a high quality even surface for absorbent masonry substrates. It is a prepacked cement render supplied in a dry powder form requiring the addition of water.

Acratex® Roofing

Acratex® Roof Membrane is a 100% acrylic coating. Our latest, innovative formula provides easier application, better gloss and less chalking - so colours stay fresher and the finish lasts longer.

Acratex® Texture

- Exterior

Acratex® products provide a textured finish that protects against render cracking and staining, to keep homes looking great for longer.

Acratex® Venetian® Plaster

From the natural beauty and charm of Marmorino Naturale to the highly polished elegance of Polished Stucco, the appeal of authentic polished lime plaster is captured and recreated in the Venetian® Plaster Collection.

Creativo® Microcement

Dulux Creativo® Microcement offers aesthetic and technical solutions that deliver a seamless look for both horizontal and vertical surfaces inside and outside your home. Its no-grout, high-end concrete look is as sophisticated as it is functional.

Envirosolutions®

- Clean up

- Paint disposal

The Dulux Envirosolutions range provides you with responsible solutions when it comes to paint cleanup. Paint washings should never be poured down the drain and solid paint waste must be disposed in accordance with local water and waste management authorities.

Metalshield®

- Exterior Paint

Whether you're painting a wrought iron fence, letter box or detailed metal trim, Dulux Metalshield® comes in a range of easy to apply products for a glossy, polished finish that lasts.

Design Effects

- Interior Paint

- Exterior Paint

Our Design Effects Collection helps you add those special details that make a home unique. Create a statement wall, highlight an architectural feature or add a luxurious finish to home accessories.

Duramax

- Interior

- Exterior

Dulux Duramax is a range of high performance spray paint that provides long lasting colour, texture and finishes for your home projects.

Professional® FASTFINISH™

- Interior

Professional® FASTFINISH™ is a unique range of trade painters to get the job done quickly. The range is optimised for spray application with a premium paint finish.

Avista®

- Interior

- Exterior

Add colour, texture and patterns to new internal and external concrete or rejuvenate existing commercial and residential concrete surfaces with Avista®. Our range includes oxides for colouring new concrete, exterior resurfacing products, internal flooring epoxy products, concrete sealers as well as stamped impression and stencil pattern applications.