Acratex® Acraskin®

About Acratex® Acraskin®

Acratex® Acraskin® is an optimised crack bridging, elastomeric membrane coating applied by conventional nap roller or medium texture roller delivering a weatherproofing, highly flexible crack-bridging coating. It provides a finish with excellent water resistance & barrier properties against moisture ingress, carbonation and surface cracking, at the same time significantly improving the buildings aesthetics.

Available in Trade Outlets only, applying this product may require professional painter assistance. Check your local stockist for details.

Downloads

Application

At a glance

- Flexibility

- Vapour permeabilty

- Durable

- Water resistant

- 9 times dry film thickness

- Crack bridging

Areas to use

Surfaces

Masonry substrates

Previously Painted Surfaces

Relative to Project Substrate and Specified Finish - refer to Project Specific Duspec Specification and Acratex® Substrate Guide.

Brush, roller

Brush, Roller, Medium Textured Roller, Airless Spray.

When cutting in edges, brush and roll-in a continuous process to avoid differences in gloss level. Application on single areas should be completed uniterrupted.

All independent tests are available on request.

Product should be thoroughly mixed before use.

Refer to the Dulux Acratex Application Manual for detailed application instructions.

Nap roller finish:

Apply 2 coats (minimum) using a 10 - 20mm Nap roller at 4 sq.m / litre

Low profile texture (requires higher material consumption):

Apply 1 coat with a low profile black Texture Roller at 2-3 sq.m / litre

Apply a 2nd (finishing coat) with a nap roller at 4 sq.m / litre

Unused paint

Unused paint: Do not pour leftover paint down the drain. Unwanted paint should be brushed out on newspaper and allowed to dry, and then disposed of via domestic waste collections. Empty paint containers: Leave empty paint containers open in a well-ventilated area to dry out. When dry, recycle the container via steel can recycling programs. Disposal of empty paint containers via domestic recycling programs may differ between local authorities. Check with your local council first. Do not reuse container unless thoroughly decontaminated. For more information on responsible disposal of paint and packaging visit paintback.com.au or painttakeback.co.nz

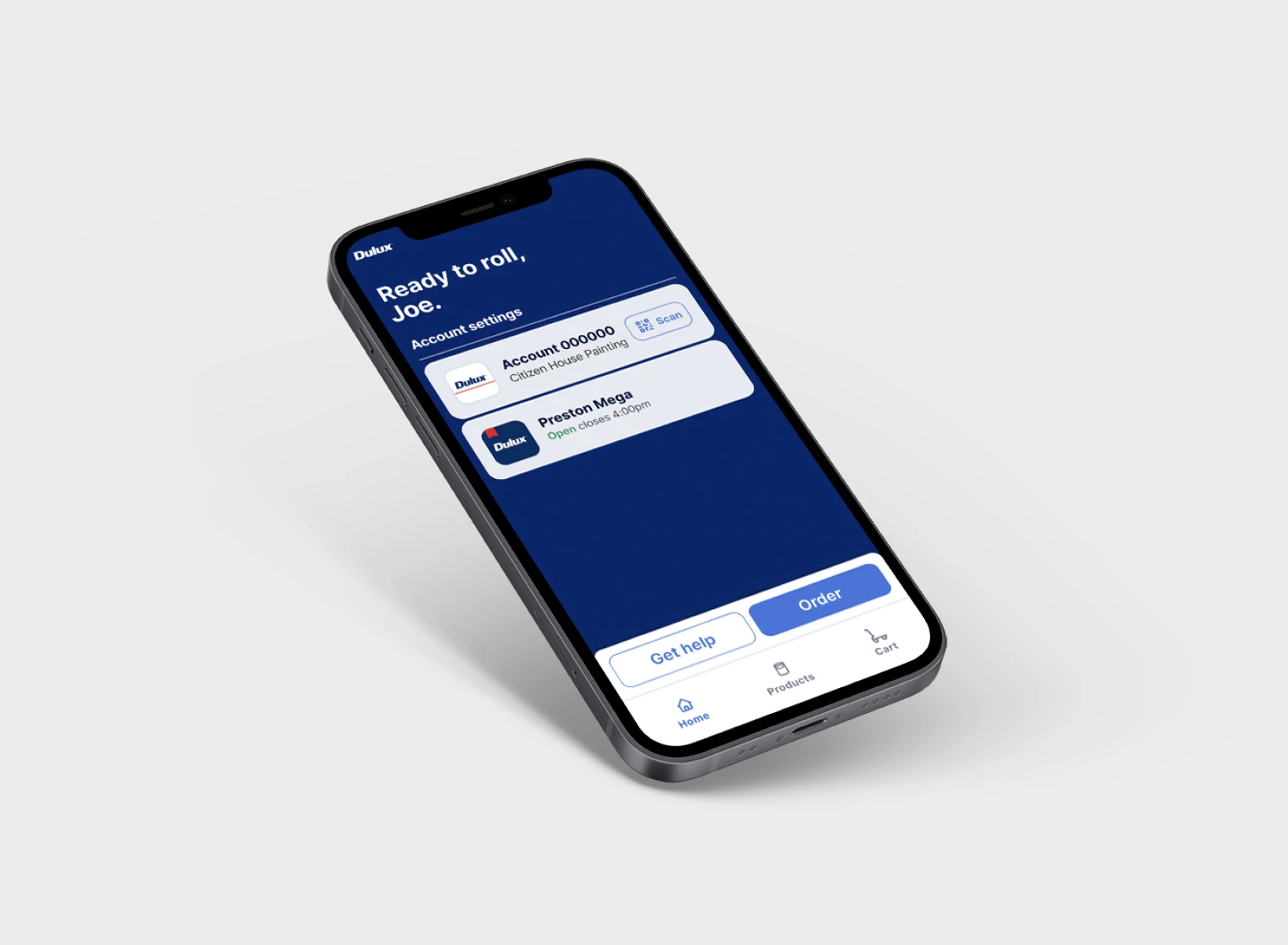

Access everything you need at your fingertips

Shop smart, shop easy

Shop with us when you want, how you want! Take control of your DuluxTRADE online account to order, track, pay and more — download the app today!

Get detailed information about the physical and chemical properties of our products.

Advice for those challenges that arise in your busy and varied days

Access product datasheets, specifications, substrates, substrate preparations, safety datasheets (SDS) and create a project specification from the ground up.