Acratex® Elastomeric 201

About Acratex® Elastomeric 201

Acratex® Elastometric 201 is a mid-build, water based coating providing superior weatherproofing and anti-carbonation properties. It delivers an enhanced crack bridging performance with excellent water resistance and protective properties against moisture ingress, carbonisation and surface cracking.

Available in Trade Outlets only, applying this product may require professional painter assistance. Check your local stockist for details.

Downloads

Application

At a glance

- Excellent water and dirt resistance

- Easy, safe and economical clean up

- High water tightness

- Paint like appearance with film builds two times standard decorative

- Available in matte only across pastel, deep and ultradeep Dulux colour ranges

- Higher cement content

Previously Painted Surfaces

Relative to Project Substrate and Specified Finish - refer to Project Specific Duspec Specification and Acratex® Substrate Guide.

Brush, roller

Acratex® Elastomeric 201 is applied by nap roller at 4 sqm/l per coat in a two coat application for a to a achieve semi-smooth finish. For full details refer to individual Duspec Product and Acratex® Applicational Data Sheets.

Unused paint

Unused paint: Do not pour leftover paint down the drain. Unwanted paint should be brushed out on newspaper and allowed to dry, and then disposed of via domestic waste collections. Empty paint containers: Leave empty paint containers open in a well-ventilated area to dry out. When dry, recycle the container via steel can recycling programs. Disposal of empty paint containers via domestic recycling programs may differ between local authorities. Check with your local council first. Do not reuse container. For more information on responsible disposal of paint and packaging visit paintback.com.au or painttakeback.co.nz

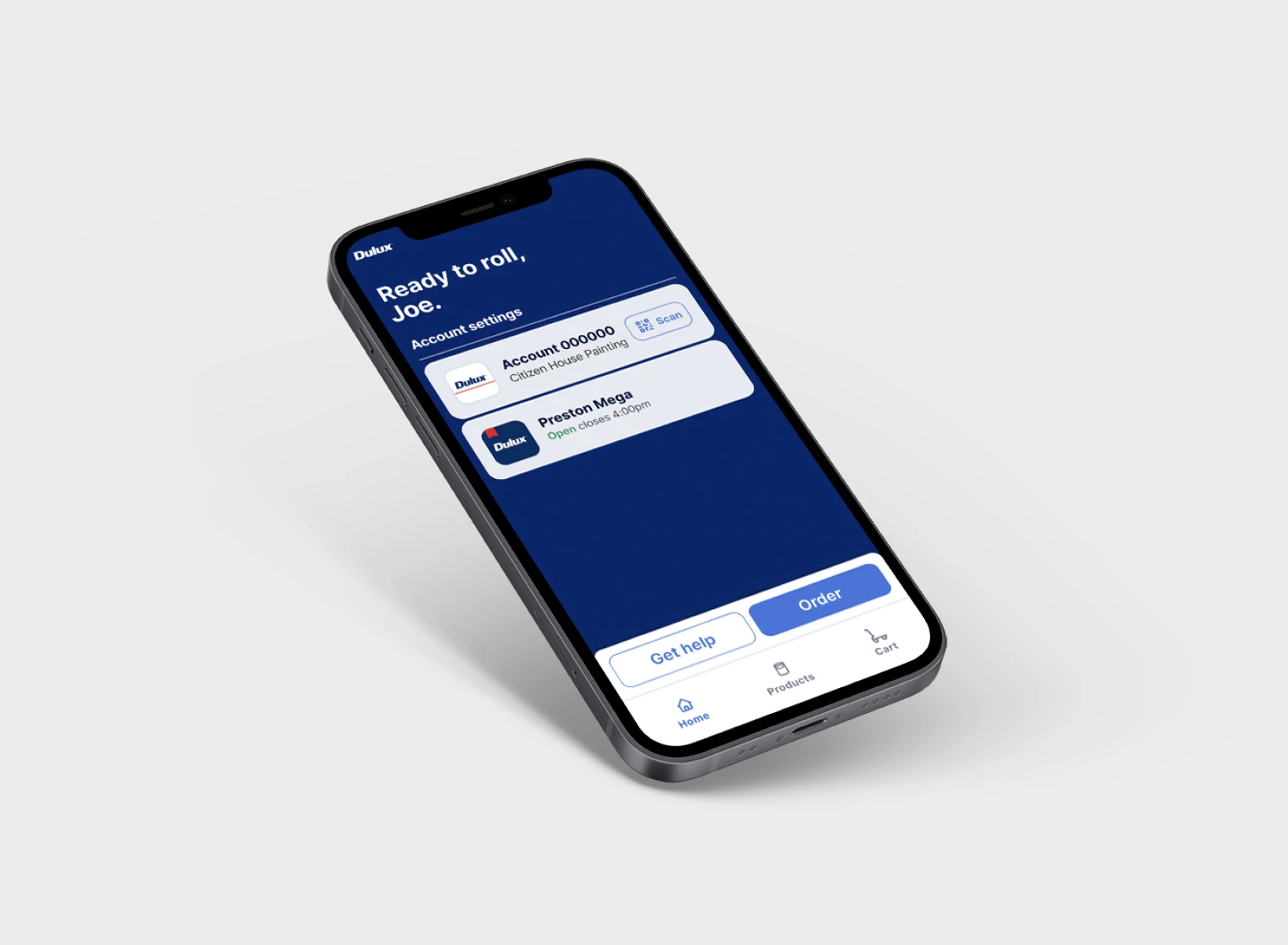

Access everything you need at your fingertips

Shop smart, shop easy

Shop with us when you want, how you want! Take control of your DuluxTRADE online account to order, track, pay and more — download the app today!

Get detailed information about the physical and chemical properties of our products.

Advice for those challenges that arise in your busy and varied days

Access product datasheets, specifications, substrates, substrate preparations, safety datasheets (SDS) and create a project specification from the ground up.