Dulux Acratex®

Dulux Acratex® coatings provide fit-for-purpose system solutions for any newly constructed or existing buildings in need of full remediation, re-paint, or refurbishment. Supported by a project specification and technical service team our Acratex® range includes non-combustible renders, flexible protective membranes, anti-carbonation coatings, acrylic textures, specialty finishes, roof membrane coatings, and lightweight wall cladding system.

Acratex® coatings and systems

All you need in one place

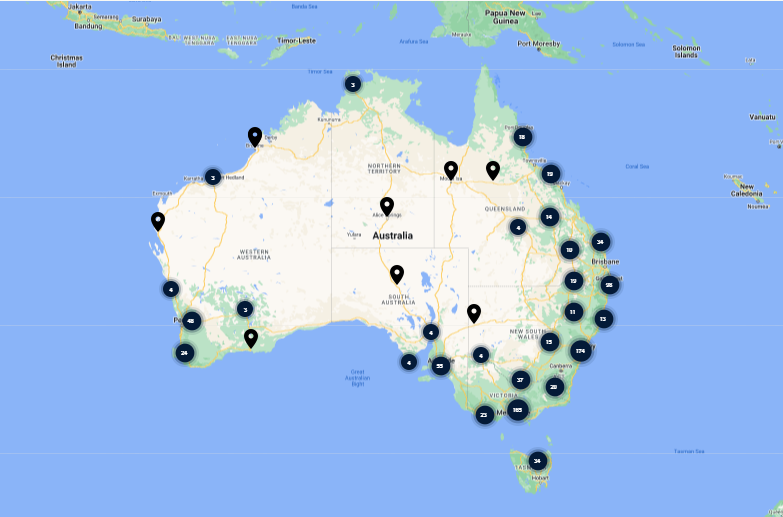

Acratex app

The Dulux Acratex® app enables you to have easy access to Acratex® brochures, datasheets, textures and colours at the touch of a button, with easy-to-send or download options. Use the interactive map to find your nearest supplier, and perhaps best of all – it includes a material calculator to help you with your next project.

Dulux Acratex® coating systems have been transforming properties for years including these outstanding case studies. Imagine the benefits and improvements that Dulux Acratex® can deliver for your residential or commercial project!

Improve your home significantly with a roof restoration that keeps your home looking great for longer, using Dulux Acratex® Huetech® technology. The Dulux Acratex roofing system will enhance your home’s street appeal and extend the life of your roof by keeping your home protected with a 15-year warranty on product performance.

Resources

Builders pack and specialty finishes samples

Order your builders pack and specialty finishes samples.

Order Dulux Acratex® samples

Order texture, render, and specialty finish samples.

Technical notes, guides and FAQs

Read our frequently asked questions and download information on Acratex® products, care and maintenance guides, and helpful tips.

BIM Solutions

Add Dulux colours and product ranges to your Revit® and Archicad® projects with ease.

Dulux Construction Solutions

Dulux Construction Solutions helps you design and build with confidence and provides access to all Dulux product solutions in one convenient place.

DuSpec+

Access technical product information and create project specifications.

Safety data sheets

Detailed information about the physical and chemical properties of Dulux products is available online.

Join Dulux Rewards

Join today and redeem your points for great rewards from your favourite stores.

Store Locator

Search by city, suburb or postcode to find your nearest store

Project gallery

Click through to see a small collection of our Acratex® coatings at work on some commercial, residential and infrastructure projects.