Technical Advice

Dulux Aquanamel Application Guide

Follow these guides and videos on brush, roller and spray application to get the best finish on your next job.

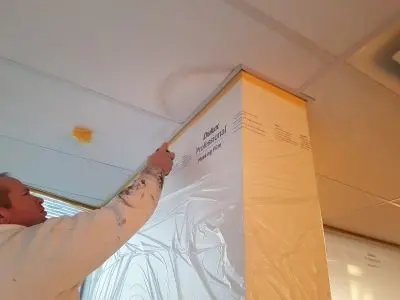

Acousticoat Ceiling Tile Paint

Dulux Professional Acousticoat is a specialist paint coating that has been designed for a specific purpose. Due to its specialist nature, it has to be applied correctly to achieve the desired finish and performance.

Spray painting and back rolling

Back-rolling is the term most often used in the paint industry to describe the manual process of dry rolling the freshly painted surface with a short to medium nap synthetic roller.

Air assisted & airless spraying advice

The 'how to' guide for spray application - air assisted & airless spraying.

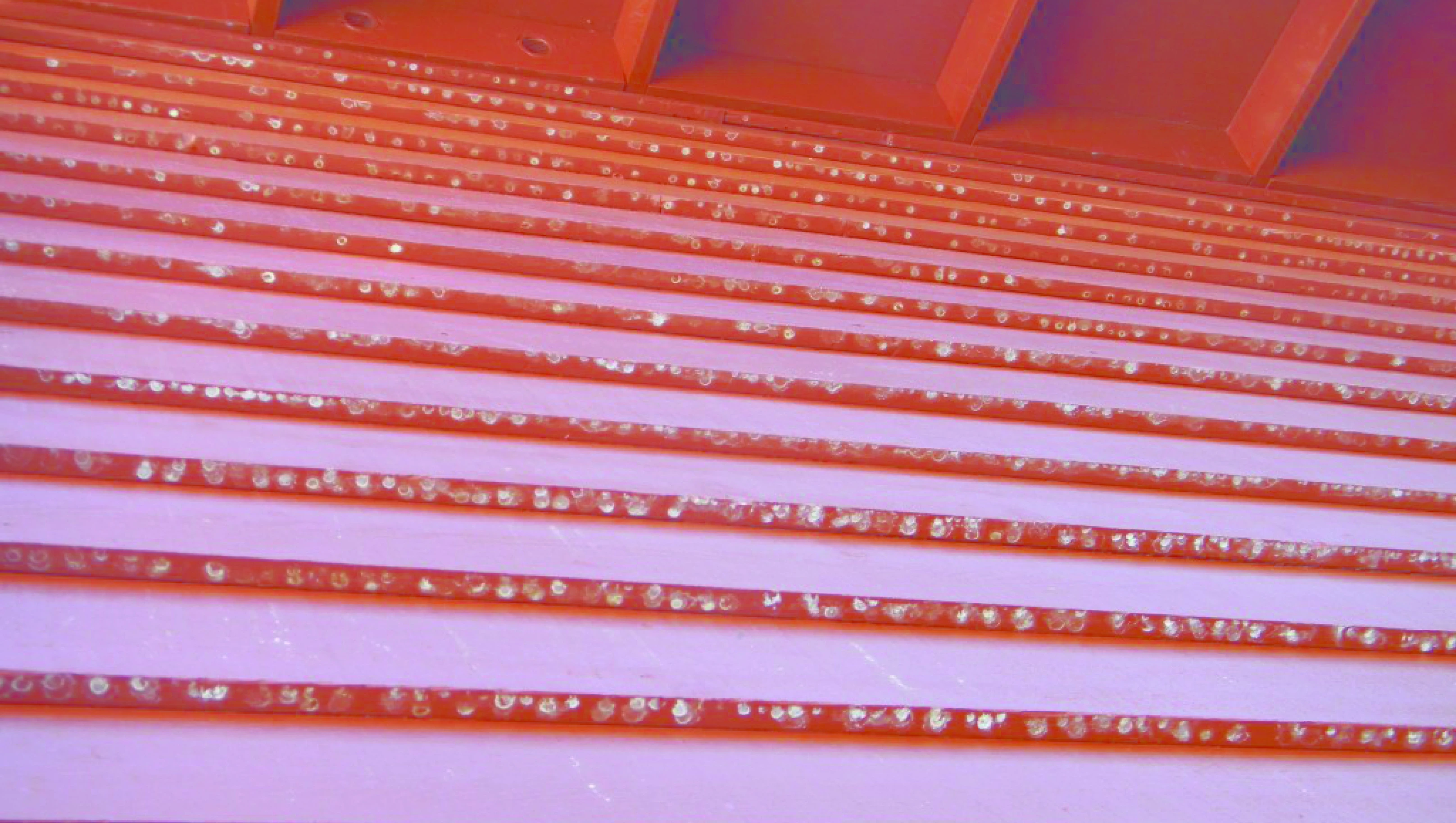

Surfactant leaching

Have you noticed small droplets appearing on your fresh coat of acrylic paint? This is known as 'surfactant leaching'. Don't panic - it's a normal part of the curing process.

Low VOC paint

The VOC solvents act to slow the initial drying by maintaining a 'wet-edge' which gives a longer time to work with the product.

Drying and hardening of water-based paints

All water-based paints undergo a “drying process” involving two distinct phases, evaporation and coalescence.

Get detailed information about the physical and chemical properties of our products.

Advice for those challenges that arise in your busy and varied days

Access product datasheets, specifications, substrates, substrate preparations, safety datasheets (SDS) and create a project specification from the ground up.